About

The Science of Carbon Nanotubes

Carbon Nanotubes are 100 times stronger than steel, have 1,000 times higher current capacity compared to copper, and are 10,000 times smaller than human hair.

Companies have been using CNTs for years. What makes Elect Nano different?

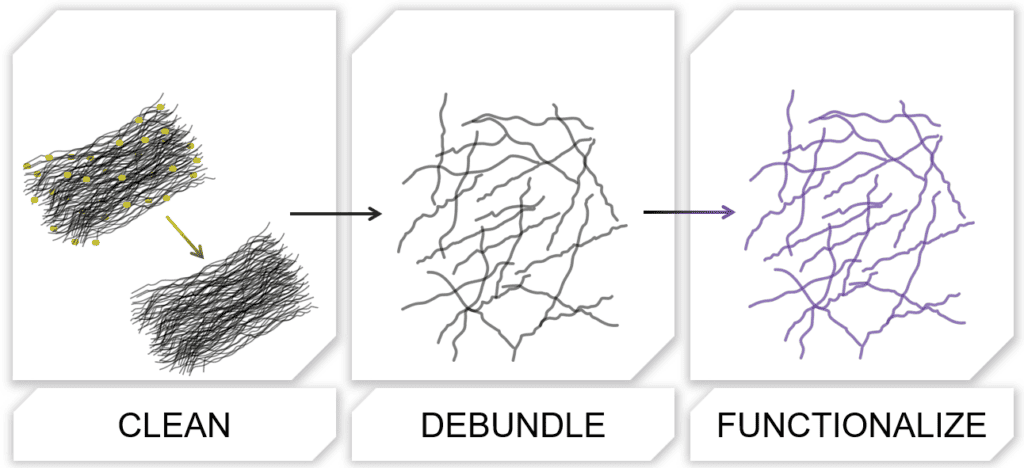

CNTs have a tendency to clump together during the manufacturing process, and the bundled CNTs are extremely difficult to untangle. The process of untangling the nanotubes is at the core of Elect Nano’s technology. Why? Because untangled tubes can produce much more uniform materials. Elect Nano’s nano uniform materials are exponentially superior in performance than materials manufactured with clumped tubes.

Elect Nano’s Process

- Clean: The cleaning process washes all the residual contaminates from the CNTs, including unwanted residual elements from the manufacturing process, such a catalysts.

- Debundle: Using our proprietary dispersion process, the nanotubes are debundled resulting in discrete CNTs.

- Functionalize: The functionalization process is where Elect Nano’s core competency in chemistry is applied. The outer walls of the discrete nanotubes are chemically modified to attach chemical functional groups. The functionalized discrete nanotubes are chemically bonded to the base material. Incorporating clean, discrete, functionalized CNTs into a variety of materials results in improved mechanical, electrical, thermal, chemical and other physical properties.

Our scientists have mastered the process of matching the nanotube chemistry to the host matrix chemistry for the final material properties required in any application. Elect Nano is then able to leverage our in-house production capabilities to scale validated nanotube chemistries to metric ton quantities and beyond.

Embedding the functionalized nanotubes is ultimately the key to unlocking next-generation electronic materials.

Accomplishments & Readiness

Based in Mesa, AZ, Elect Nano has the largest functionalized CNT manufacturing facility in the world and offers the world’s ONLY discrete, functionalized, dispersed Carbon Nanotubes (dCNTs). We own exclusive rights to over 120 patents, including dCNT “composition of matter” patents.

Our technology will enable higher reliability components, better EMI shielding, and nano uniform materials on an atomic scale.